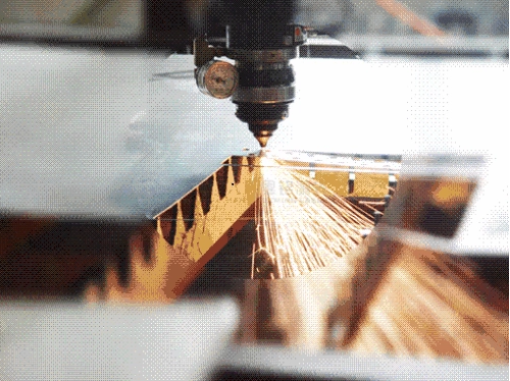

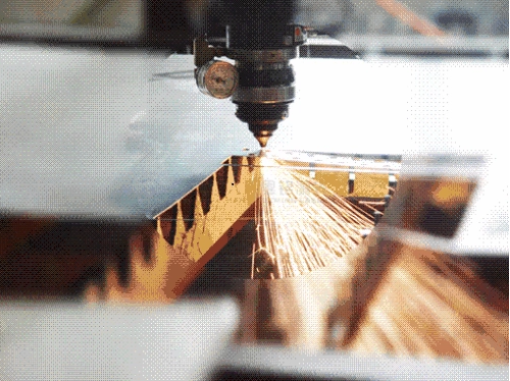

Laser cutting is widely used in the process of processing and cutting technology, the development of laser cutting technology is further accelerated, the development of laser cutting technology can make the technology in the process of application more reflect its advanced, from the current development situation, laser cutting technology toward the development of the following directions.

Cutting quality

Cutting accuracy is to judge the quality of CNC Laser Cutting Machine elements, four factors affecting the cutting accuracy of CNC laser cutting:

1, laser generator laser condensation size. After gathering if the light spot is very small, the cutting accuracy is very high, if the gap after cutting is very small. The precision of the laser cutting machines is very high, the quality is very high. But the laser beam is tapered, so the cut gap is also tapered. Under such conditions, the greater the thickness of the workpiece, the lower the accuracy will be, so the greater the slit.

2, CNC Turnin accuracy of the workbench. If the precision of the table is very high, the precision of the cutting is also improved. So the accuracy of the table is also a very important factor to measure the accuracy of the laser generator.

CNC Milling laser beam condenses into a cone. When cutting, the laser beam is conical down, then if the thickness of the cutting workpiece is very large, the precision of cutting will be reduced, and the gap will be very large.

4, cutting materials are different, will also affect the precision of laser

cutting machine, in the same case, cutting stainless steel and cutting aluminum its precision will be very different, stainless steel cutting precision will be higher, and the section will be smooth.

Laser

Cutting Machine service to judge the quality of laser cutting machine cutting is a good way to intuitively determine the performance of laser cutting equipment, here is to give you a list of some of the nine criteria.

Roughness, aluminum laser cutting section will form vertical lines, the depth of the lines determines the roughness of the cutting surface, the shallower the lines, the cutting section is smoother. Roughness not only affects the appearance of the edge but also affects the friction characteristics. In most cases, it is necessary to reduce the roughness as much as possible, so the shallower the grain, the higher the cutting quality.

Laser cutting what needs to pay attention to X-axis guide and lead screw, Y-axis guide and lead screw, Z axis guide and lead screw lubricating oil filling must be checked every other week to maintain the lubrication of all moving parts and extend the service life of X, Y, Z-axis guide, and lead screw. B. Inspect the surface pollution of the mirror and focusing lens irregularly (at least once a month) according to the environment of the workshop, and clean the optical lens in time to ensure its service life (see the maintenance of optical lens for details)

Clean up the sundries at the outlet regularly to ensure the effectiveness of the exhaust.

Check the filter in the air path regularly, remove water and debris in the filter in time.

Check regularly whether the screw of the travel switch bracket and bump block bracket is loose.

The dust on the filter net of the electric control cabinet ventilator should be cleaned in time to ensure good ventilation and facilitate heat dissipation of the internal electrical components.

Clean the body guide rail in time to protect the impurities in the skin cavity, so as not to damage the guide rail, so as to prolong the service life of the guide rail.

After CNC Milling machine is installed and used for a period of time, the level of the machine should be adjusted again to ensure cutting accuracy of the machine.

Contact us if you need more details on Laser Cutting Service Plastic. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Custom Laser Cutting Services、Laser Cutting Service Customized. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Laser Cutting